Current position:Home > News & Events > News

Common MBBR Ammonia Removal Failure Causes Operators Often Overlook

Common MBBR Ammonia Removal Failure Causes Operators Often Overlook

In many municipal, industrial, and aquaculture MBBR installations, the top frustration for operators is underperforming ammonia removal that fails to meet design expectations. The good news is that the issue rarely stems from media quality, process design, or wastewater characteristics—instead, it often lies in subtle operational oversights that engineers may miss initially.

Below are the 6 most frequent root causes of MBBR ammonia removal failure we’ve identified across hundreds of real-world projects, paired with data-backed solutions and industry cases to help you resolve issues quickly.

1. DO Setpoints Too Low for Nitrifiers

Nitrifying microbes are slow-growing and highly oxygen-sensitive. Research shows that when DO levels are consistently below 2.0 mg/L, MBBR ammonia removal efficiency drops by 30–50% compared to optimal conditions.

Typical issues include fixed-speed blowers (unable to adjust airflow based on demand), partially clogged diffusers (reducing oxygen transfer), and operators reducing aeration to cut energy costs.

Real Case: A municipal MBBR system in the Midwest struggled with 65% ammonia removal efficiency—tests revealed DO stayed at 1.7 mg/L due to fixed-speed blowers and clogged diffusers. After switching to variable-speed blowers and implementing monthly diffuser cleaning, DO stabilized at 2.8 mg/L, and ammonia removal rate jumped to 92% in 2 weeks.

Recommendations: Maintain DO levels between 2.0–3.5 mg/L in nitrification MBBRs (critical for MBBR ammonia removal in high-load scenarios) and verify diffuser airflow distribution monthly to avoid localized low oxygen.

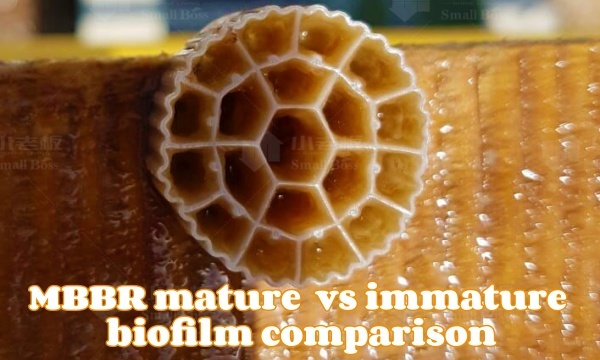

2. Biofilm Not Fully Mature Common in New Start-ups

Many operators evaluate MBBR ammonia removal performance too early, leading to unnecessary concerns. A stable nitrifying biofilm requires 3–8 weeks to develop, depending on temperature (longer in cold weather, shorter in 20–25°C environments).

Signs of immature biofilm include thin, pale appearance, day-to-day performance fluctuations (ammonia removal rate varying by 15%+), and higher-than-usual nitrite levels (exceeding 1 mg/L).

Key Data: Biofilm maturity directly impacts stability—mature biofilms reduce ammonia removal fluctuations by 50% and improve resistance to shock loads. Avoid judging ammonia removal effectiveness in the first month; prioritize verifying biofilm thickness (ideal: 100–300 μm) and microbial diversity first.

3. Temperature Below Biological Optimum

Nitrification slows dramatically when temperature drops below 15°C (removal rate decreases by 10–15% per 1°C drop) and nearly stops below 10°C. This is the top cause of MBBR ammonia removal issues in cold regions or winter operations.

Key checks: Inlet temperature history (track over 3 months to identify seasonal trends), seasonal variations, and heat loss in uncovered open tanks (which can lower water temperature by 3–5°C in cold climates).

Solution: If water is too cold (below 15°C), increase HRT by 20–30% or add an equalization step to reduce temperature shock. For MBBR ammonia removal in cold regions, insulating open tanks or adding a heating system can boost efficiency by 25–40%.

4. Organic Overloading Outcompetes Nitrifiers

Poor upstream treatment can shift the COD/NH? ratio (optimal ratio: 5:1–10:1), allowing heterotrophs to dominate the biofilm—they consume oxygen and space, suppressing nitrifier activity.

Symptoms include high COD spikes (exceeding 500 mg/L), unstable DO profiles (fluctuating by 1 mg/L+ within hours), and darker, thicker biofilm (prone to sloughing).

Industrial Case: A food processing MBBR system faced frequent COD overloads (COD/NH? ratio reached 20:1), leading to ammonia removal dropping to 58%. After adding a small pre-MBBR aerobic step to stabilize COD load, the ratio normalized to 8:1, and ammonia removal recovered to 90% within 3 weeks.

Solution: Stabilize COD load through upstream process optimization or add a small pre-MBBR treatment step—critical for industrial MBBR COD overload solution and consistent ammonia removal.

5. Uneven Mixing or Media Deposition Zones

Poor mixing reduces contact between MBBR media and oxygen, leading to localized low DO, anaerobic biofilm formation, and ultimately poor ammonia removal (often uneven across the tank).

Common causes: Low aeration in tank corners, dead zones in rectangular tanks (accounting for 10–15% of tank volume), and carriers trapped behind baffles.

Impact Data: Dead zones can reduce effective tank volume by up to 20%, lowering overall treatment capacity. Adjust diffuser layout to cover corner areas or increase point aeration in problem zones—this simple fix improved ammonia removal by 30% in an aquaculture MBBR system we serviced.

6. pH or Alkalinity Too Low

Nitrification consumes alkalinity rapidly (10 mg alkalinity as CaCO? per 1 mg NH?-N removed). When alkalinity drops below 60–80 mg/L as CaCO?, nitrifiers slow down significantly, and pH often falls below 6.5 (the minimum optimal pH for nitrification).

Checks: Is pH below 6.5? Is alkalinity below 80 mg/L? For aquaculture MBBR alkalinity control, consistent monitoring is key—fluctuations can stress both nitrifiers and aquatic organisms.

Solution: Consider adding alkalinity (such as NaHCO?) at a rate of 12–15 mg/L CaCO? per mg NH?-N to be removed, or improve upstream buffering to maintain stable pH and alkalinity.

Conclusion & Free MBBR Operational Diagnosis Offer

When MBBR ammonia removal declines, many operators immediately suspect media issues or design flaws. However, in over 80% of cases we’ve observed, the root cause relates to DO levels, mixing efficiency, biofilm maturity, alkalinity, temperature, or organic shock loads.

By following this checklist, most MBBR systems can quickly restore nitrification performance and avoid unnecessary redesign or troubleshooting.

Need Personalized Support? Our team of MBBR experts offers free operational diagnosis for municipal, industrial, and aquaculture systems. Whether you’re dealing with cold-region ammonia removal, COD overload, or biofilm issues, we’ll provide a tailored solution to meet your design performance. Contact Small Boss todayto claim your free MBBR operational diagnosis – get your ammonia removal system back on track with a tailored solution!

Chinese

Chinese  English

English Espa?ol

Espa?ol Русский

Русский